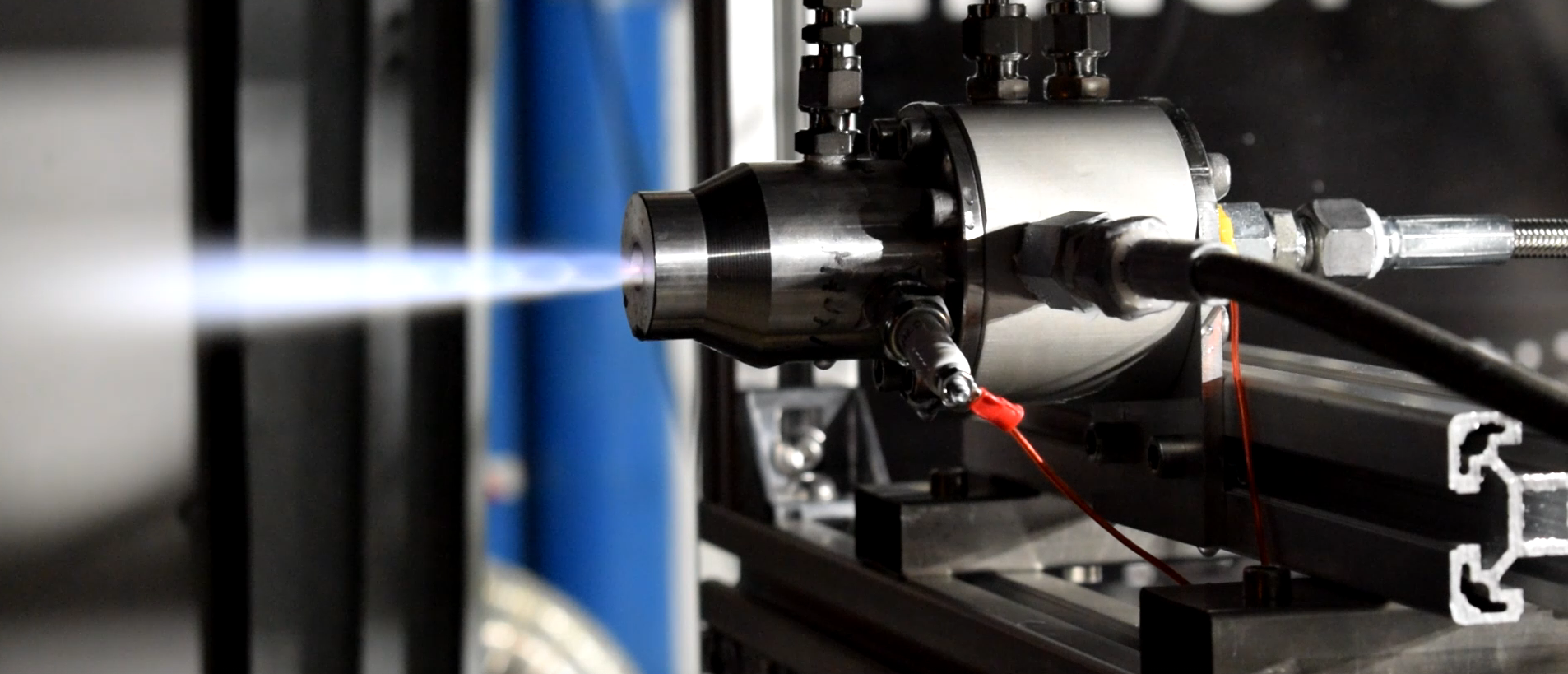

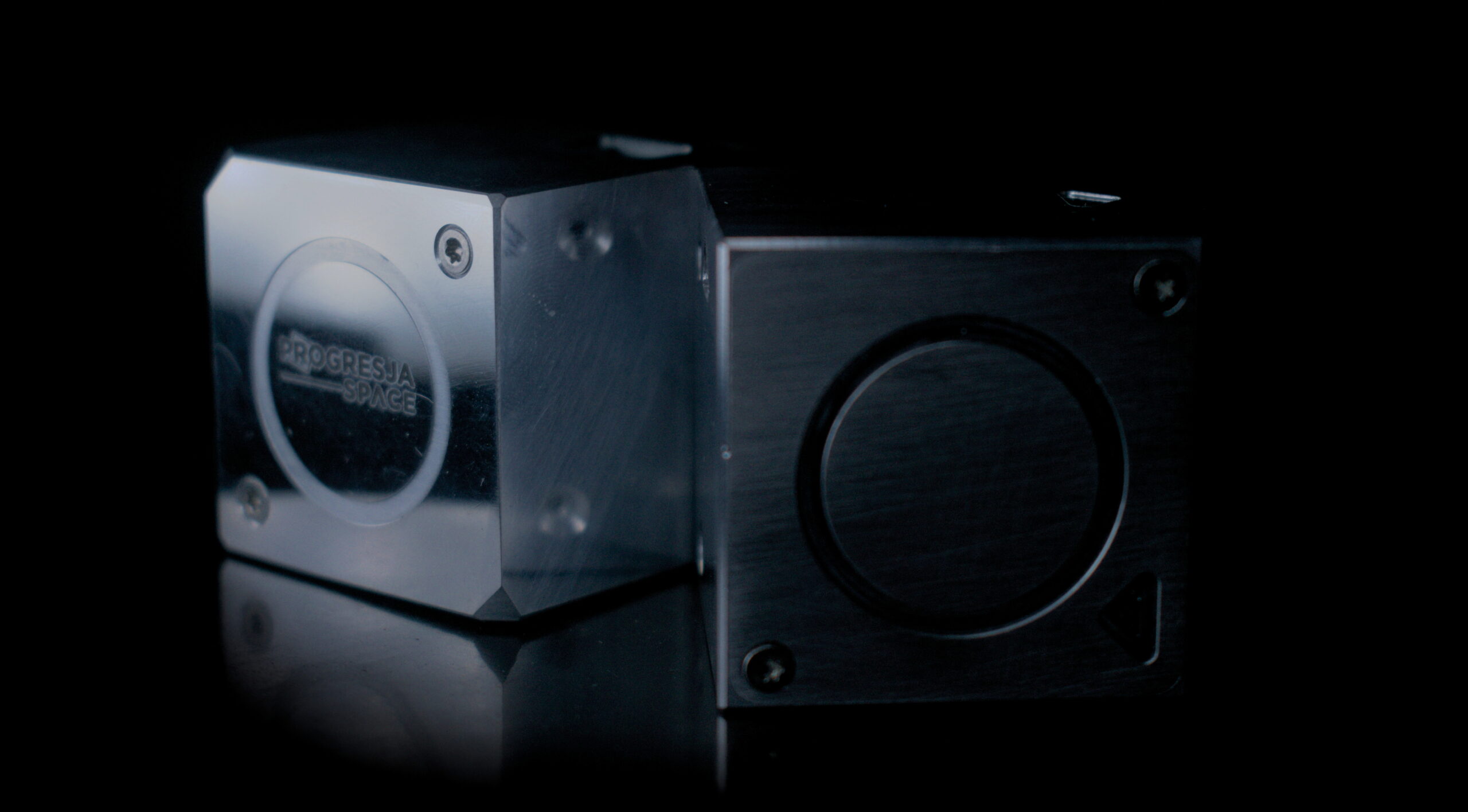

High-temperature thrust chambers

Refractory thrust chambers for chemical thrusters

We can design and manufacture thrust chambers, including nozzle and injectors according to your requirements. The materials include In718, Nb-Hf C103, rhenium, and PtRh20.

TRL 6

-

25 %

Mass savings

Improved design allows for significant mass savings

-

30 %

Affordable

Up to 30% cost reduction compared to the traditional thrust chambers

-

50 %

Short lead time

Waiting time reduced down to 3 months thanks to in-house capabilities and processes.

| Parameter | Range | Units |

|

Nozzle throat diameter |

1 - 15 | mm |

|

Nozzle exit diameter |

20 - 300 | mm |

|

Total length |

50 - 350 | mm |

|

Wall thickness |

0.3 - 5 | mm |

|

Chamber internal diameter |

5 - 50 | mm |

Inconel 718 (IN718) is a nickel-based superalloy known for its high strength and excellent corrosion resistance, making it a go-to material in high-temperature applications. Within the context of thrust chambers, IN718 is primarily employed in the construction of injectors and nozzle extensions. Its relatively low melting temperature makes it especially suited for these components. Adding to its advantages is its cost-effectiveness, making it an affordable option without compromising on performance. One of the standout features of IN718 is its adaptability to 3D printing technologies, allowing for the creation of complex shapes, including the integration of cooling channels. Our rigorous tests have shown that IN718 can withstand temperatures as high as 1100°C, making it a reliable choice for high-temperature thrust chamber components.

Nb-Hf C103 alloy is a high-performance niobium-based material, enriched with hafnium and zirconium, that boasts exceptional mechanical properties and resistance to high temperatures. In the realm of thrust chambers, C103 is an ideal candidate for components exposed to extremely high temperatures, capable of performing reliably up to 1500°C. However, to harness its full potential in oxidizing environments, it is essential to apply silicide coatings for effective oxidation protection. Like IN718, C103 is highly versatile and can be manufactured into complex geometries, but its standout feature is its capability to endure extreme temperatures. The application of silicide coatings not only protects the alloy but also enhances its longevity and reliability in operational settings. All these attributes make Nb-Hf C103 a robust and dependable choice for the most demanding high-temperature applications in thrust chambers.

Rhenium is an exceptional material renowned for its high melting point, remarkable mechanical strength, and superior resistance to wear and corrosion. In thrust chamber applications, rhenium truly excels, capable of maintaining its integrity and mechanical strength at temperatures up to 1600°C. Its robustness at such extreme temperatures sets it apart from most other materials, making it the choice for critical, high-temperature components. To further capitalize on its capabilities, rhenium components are usually coated with iridium through Chemical Vapor Deposition (CVD) to protect against oxidation, thereby enhancing its longevity and operational reliability. This added layer ensures that the material’s extraordinary properties are preserved even in the most challenging oxidizing environments. While rhenium comes at a premium cost, its unparalleled performance at high temperatures often justifies the investment, positioning it as a high-end, indispensable option for the most demanding high-temperature requirements in thrust chamber technology.

PtRh20, a high-end platinum-rhodium alloy, is another exceptional material choice for thrust chamber applications. Though it doesn’t possess the extreme mechanical strength of rhenium, it has the remarkable ability to withstand temperatures up to 1600°C. What sets PtRh20 apart is its ductility, providing a different kind of advantage under extreme conditions. This unique combination of high-temperature tolerance and ductility makes it a valuable option for specific applications within thrust chambers that require a blend of both properties. Similar to rhenium, PtRh20 maintains its structural integrity at elevated temperatures, but its higher ductility allows for some design flexibilities that may not be possible with more rigid materials. This platinum-rhodium alloy stands as a high-end choice, suitable for specialized high-temperature applications where a balance between material strength and ductility is required. Its unique characteristics position PtRh20 as a premium material option for the most challenging high-temperature environments in thrust chamber technology.

Technical specification and pricing on request

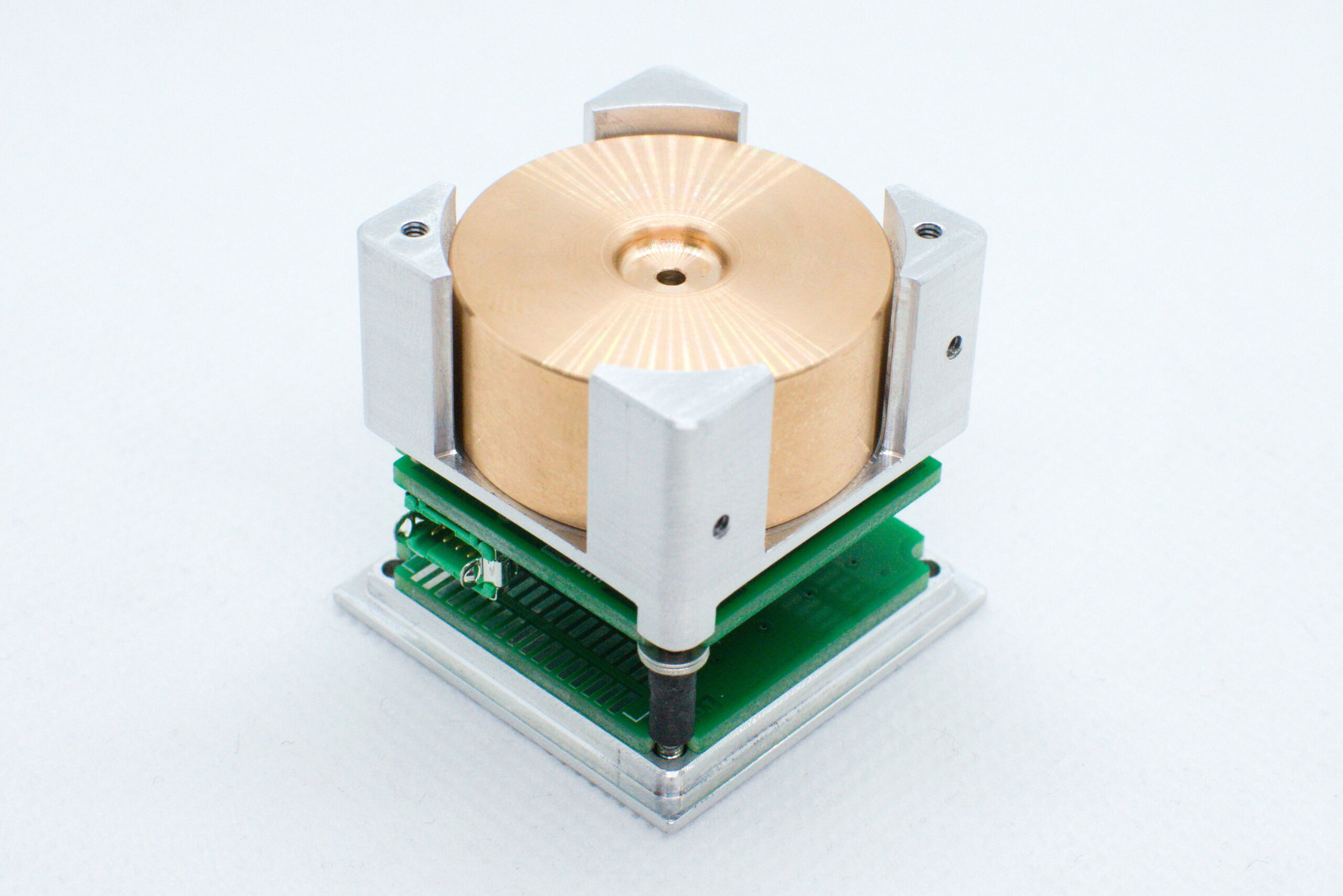

Reaction wheel for nanosatellites

MRW 35 reaction wheel series

We designed and tested compact and capable reaction wheel for ADCS subsystems for nano-satellites between 3 - 16U.

TRL 6

-

10 %

Momentum storage

Improved momentum storage allow for better satellite control

-

20 %

Low power

We lowered power consumption both during standy and operation by up to 20%

-

50 %

Torque

Our reaction wheels have unparalleled torque available for your slew manoeuvres